Description

Hydraulic Scraper Components

Power Unit

• Special Heavy Duty hydraulic pump with high efficiency low noise level

• Special Heavy Duty hydraulic pump with high efficiency low noise level

• Custom Made hydraulic oil filter, to reduce any dirt in the oil and to increase the life of the hydraulic system

• Soft turning changeover valve gives smooth operation with no disturbance to the cows

• Easy adjustable turning pressure for individual plant control

Control Panel

• Manual or fully automatic operation

• Manual or fully automatic operation

• Manual operation – Each Passage can be started manually and when the scraper completes its cycle it returns to the home position and parks.

• Automatic operation – Each passage will start automatically at preselected intervals using a 24hr clock and when the scraper completes its cycle it returns to the home position and parks.

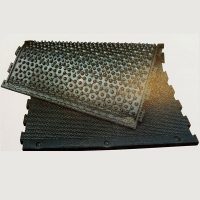

Passage Scraper Blade

•Robust all galvanised construction and animal friendly design

•Robust all galvanised construction and animal friendly design

• Built in safety trip mechanism ensures that the scraper returns to its parking position if passage is blocked.

• Floating blades give excellent cleaning and first class hygiene results.

• Blade constructed from 12mm steel with 20mm heels for long life.

Rambox

• Long and short rambox available for maximum flexibility

• Long and short rambox available for maximum flexibility

• Unique parking switch for positioning the scraper at the end of each passage

• All Galvanised

• Separate cylinder cover facilitated inspection and easy service

• Glanded Junction Box

Track

- Cow friendly design with curved notches

- 5mm all galvanised steel after manufacturing.

- Guide bracket every 1500m

Undertrack Ram Assembly

• Allows blade to park close to wall, resulting in cleaning of full passage

• Allows blade to park close to wall, resulting in cleaning of full passage

• Causes no obstruction in passage or doorway

• Suitable for all types of shed designs

• Unique sensor parking system.

Technical Data

Cylinder – 45/30 x 500mm

Scraper Height – 175mm effective

Passage Length – Max. 120m

Passage Width – 1.6 – 5.0m

Clearance under slatted floor – Min. 300mm

Powerpack – 1.5Kw – 2.2Kw

Rambox Long – 115 x 300 x 1250 mm

Rambox Short – 115 x 300 x 650 mm