Description

The Alfco Rope Scraper Components:

Control Panel:

• Can be easily programmed using our user-friendly keypad.

• Can be easily programmed using our user-friendly keypad.

• Works manually or can be set to come on automatically at present intervals.

• If it detects an animal lying on the passage it will reverse and stop. It will then go forward again after 1 min.

• If it detects an animal again it will reverse and shut down until it is manually restarted

• Three power settings (1. For Motor start up, 2. Normal running power, 3. Cow down protection)

• By using the invertor, we have maximum control over our scrapers. This allows the motor 30 seconds to reach its maximum speed on start-up resulting in reduced wear on the gearbox and rope.

Corner Pullies:

• Pulley Housing, made from 6mm galvanised steel.

• Pulley Housing, made from 6mm galvanised steel.

• Can be floor or wall mounted.

• Pulley made from acetal.

• Rotates on a stainless-steel pin.

• No need to grease and will have very little wear

Drive Winches:

• Made from heavy gauge hot dipped galvanised steel.

• Made from heavy gauge hot dipped galvanised steel.

• Can be floor or wall mounted.

• Water proof sensors placed in the drum are used to control speed and parking

• Scraper runs at a constant speed of four meters a minute but slows down as it approaches the slatted tank allowing more time for the slurry to flow away.

• The sensors detect a marker placed in the rope for accurate parking.

• This is backed up with a counter that counts the number of revolutions on the winch drum.

• Programmed to gradually slow down when parking at the end of the cleaning cycle resulting in no catapult action to injure or frighten animals.

• Three motor and gearbox options depending on length of passages

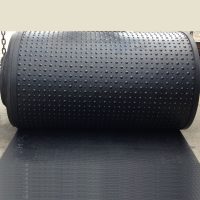

Rope:

• 12 mm dynema rope.

• 12 mm dynema rope.

• Minimum breaking load 16.4 Tons.

• No stretch characteristics.

• Extremely flexible and lightweight.

• Animal friendly

Scraper Blade:

• Robust all galvanised construction and animal friendly design.

• Robust all galvanised construction and animal friendly design.

• Blade constructed from 12mm steel with 20mm heels for long life.

• Floating blades give excellent cleaning and first class hygiene results.

• Rope can be easily attached and adjusted.